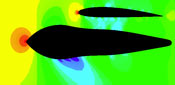

Microwave and RF Testing

Mechanical and Structural Testing

Test capabilities support materials and process evaluation, product qualification and production quality assurance.

Material Properties: Candidate design materials screening and production quality

assurance test methods for structural, mechanical, electrical and thermal

properties.

Processing Characteristics: Test methods for polymer processing characteristics,

rheology and cure cycle development.

Developmental Hardware: Destructive and non-destructive component testing to

proof manufacturing methods and correlate design and analysis data.

Non-Destructive Test: Radiographic (x-ray) and ultrasonic (UT) test standards to

establish flaw detection limits within laminates and bonded joints.

System Qualification: Test procedure and instrumentation development to qualify

composite structures for functional and environmental requirements including:

microwave and RF transmissivity, electromagnetic shielding, hydrostatic

pressure loading, fatigue loading, ballistic integrity, thermal cycling, shock,

vibration, impact and wear.